The Pros and Cons of Rebuilding Transmissions In-House

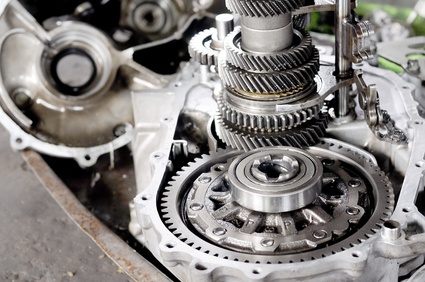

There are some options a shop has when it comes to transmissions: replace, remanufacture, or rebuild. It's obviously a shop's preference whether they feel they have the ability or the capacity to complete transmission rebuilds in-house. Pros and cons of rebuilding transmissions in-house should be looked at and considered and that's where we come in. Today, we're going to go over some of the positives and negatives of rebuilding transmissions in house.

There are some options a shop has when it comes to transmissions: replace, remanufacture, or rebuild. It's obviously a shop's preference whether they feel they have the ability or the capacity to complete transmission rebuilds in-house. Pros and cons of rebuilding transmissions in-house should be looked at and considered and that's where we come in. Today, we're going to go over some of the positives and negatives of rebuilding transmissions in house.

Advantages of rebuilding transmissions in-house

Customer Savings. Rebuilding transmissions in house allows the shop to not only identify the actual problems, but to possibly save money for customers, explains ATRA Technical Director Lance Wiggins. "Especially when the transmission can be repaired or overhauled for less than a transmission replacement."

In-House Specialist. Having a transmission specialist and rebuilder in house is a huge benefit to both the shop and to the customer. But it's only a benefit if your techs are qualified and certified. Training and paying your techs is key. "Technicians need to feel the owner is investing their time and money into their business," explains Wiggins. "Keeping your techs properly trained and educated will cut down on the amount of comebacks and keep your reputation golden." (Click here for a discussion of emerging transmission technology your techs should know.) When a transmission technician rebuilds a transmission, you avoid the hassle of receiving a defective replacement unit. And because it is being rebuilt using the original unit by an on-site, in-house specialized technician, it will be rebuilt to the quality standards of the shop.

More Eco-Friendly. Did you know that a rebuild is actually more environmentally friendly than a brand new transmission from the dealership? This is because transmission rebuilds only require worn and/or damaged parts to be repaired or replaced, whereas a new transmission requires all-new parts.

Added Shop Revenue. If a shop installs remanufactured units but doesn't rebuild transmissions in house, they are ultimately a middle man installer. Rebuilding the transmissions in house allows the shop to cut out the middle man and rebuild and install themselves, adding more revenue for the shop in the long run.

Disadvantages of rebuilding transmissions in-house

There are, of course, some added cons that come with rebuilding transmissions in house.

There are, of course, some added cons that come with rebuilding transmissions in house.

Inevitable Down Time. A transmission rebuilder can easily be the most-paid person in your shop, seeing as how the position is so specialized. You will eventually run into a time when business is slow and you'll be tasked with trying to keep your transmission rebuilder busy. This can easily be a loss of revenue as well as productivity if your transmission rebuilder doesn't have other skills beyond rebuilding units.

Loss of Time. Another con involves time. On average, it usually takes two to three days for a rebuild, depending on the transmission. This includes the diagnosis, tear down, cleaning, parts ordering and repair. But this time could be doubled to four to five days if parts supply is limited. Rebuilding transmissions in house can take much more time managing the job since now you'll have to identify the parts that need to be replaced in the unit, price out each part and ultimately obtain them. This process can be much more time intensive as opposed to simply ordering one wholly remanufactured unit. (For the pros and cons of using reman units in your rebuilds, check out our recent blog post.)

Cost of Training. To rebuild transmissions in house you'll have to invest time and money, not to mention get your techs properly trained and educated. Transmission techs should be regularly attending classes to keep up on changing technology, it's vital that shop owners respect their employees enough to invest in them. But investing can mean some costly expenses, so know going in that having a properly trained transmission tech will cost some money but can bring in more business in the long run.