Why Do Transmission Applications Have Variations?

There are numerous ways to help ensure that your transmission shop is ready for any vehicle that needs service and any transmission that needs to be rebuilt. But even if you have overhaul kits on hand, train and prepare your technicians, and optimize your shop effectively, you can still run into unexpected challenges. One of the issues many shops and rebuilders face is the dilemma of transmission application variations.

There are numerous ways to help ensure that your transmission shop is ready for any vehicle that needs service and any transmission that needs to be rebuilt. But even if you have overhaul kits on hand, train and prepare your technicians, and optimize your shop effectively, you can still run into unexpected challenges. One of the issues many shops and rebuilders face is the dilemma of transmission application variations.

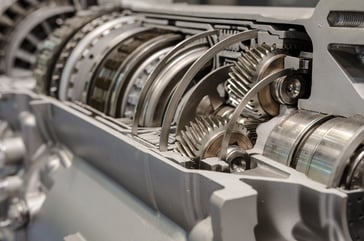

A variation is an alternate version or iteration of the same transmission application often used in multiple vehicles or models. The same overall transmission application can differ (slightly or greatly) between variations in terms of parts, design, assembly, and more. When you're not prepared to service the right variation, your rebuild is effectively put on hold until you get the parts or education you need to complete the job, halting productivity. But why do applications have variations, and how can you be ready to address them?

In this post, we'll explain the main reasons why transmission applications have variations and provide some tips for addressing variation challenges in your rebuild shop.

3 Reasons Transmission Applications Have Variations

Changes to the original application design: Some changes that account for transmission applications occur simply as the result of time. As flaws are discovered in original designs after months or years and OEMs research ways to correct those issues, an updated variation of the same application might replace the original application in future vehicles produced. While these changes don't constitute an entirely new application, they do pose an altered rebuild process. Progressive variations of this kind can reflect multiple iterations of adjustments that have been made to the application over time.

Changes to the original application design: Some changes that account for transmission applications occur simply as the result of time. As flaws are discovered in original designs after months or years and OEMs research ways to correct those issues, an updated variation of the same application might replace the original application in future vehicles produced. While these changes don't constitute an entirely new application, they do pose an altered rebuild process. Progressive variations of this kind can reflect multiple iterations of adjustments that have been made to the application over time.- Feedback from transmission professionals: Installers, rebuilders, and other transmission professionals can actually have an impact on the way that some applications are redesigned. Some manufacturers will take into account the challenges that service technicians and rebuilders face when working on their units and use that feedback to make tweaks to the design and assembly to allow for more efficient service. Some OEMs might consult their in-house technicians or dealerships as well as aftermarket professionals in order to assess what could be revised with a new variation.

- New technology or innovations: Finally, some transmission variations come as the result of new technologies or innovations that take hold across the transmission or automotive industries. When a new technological advance can improve the overall performance of a vehicle but doesn't require an entirely new transmission application, variations of the same application can potentially be created in order to incorporate the advanced update.

Addressing Variation Challenges in Your Transmission Rebuilds

While transmission application variations are produced in order to improve upon the original design for one reason or another, they can also present rebuilding challenges that can cost your shop time and money if you're not prepared to deal with them. Particularly, a transmission variation can require different parts and sealing components than other versions. If your techs are working with an outdated overhaul kit for the wrong variation of an application, they're much more likely working with incorrect or missing parts.

While transmission application variations are produced in order to improve upon the original design for one reason or another, they can also present rebuilding challenges that can cost your shop time and money if you're not prepared to deal with them. Particularly, a transmission variation can require different parts and sealing components than other versions. If your techs are working with an outdated overhaul kit for the wrong variation of an application, they're much more likely working with incorrect or missing parts.

When your kit is incomplete, your rebuild work has to be put on hold while someone in the shop researches the issue, identifies the correct variation, orders the missing or incorrect components, and waits for them to arrive. This solution adds costs on top of the overhaul kit you've already purchased, but perhaps more importantly, it slashes productivity in your shop. When you can't finish the rebuild because of a variation, your customer is without their vehicle, which is taking up valuable space in your shop. Additionally, using the wrong parts for the wrong variation, no matter how small, can ultimately cause transmission failure and result in a costly comeback for your business.

The best way to prepare for variation rebuilds is to always use a brand of overhaul kit that accounts for them. When you work with a kit provider that researches variations, provides correct and complete overhaul kits that account for the differences between units, and knows the transmission industry and the changes it's going through, you can be much more confident in your ability to service any vehicle that rolls into your rebuild shop.